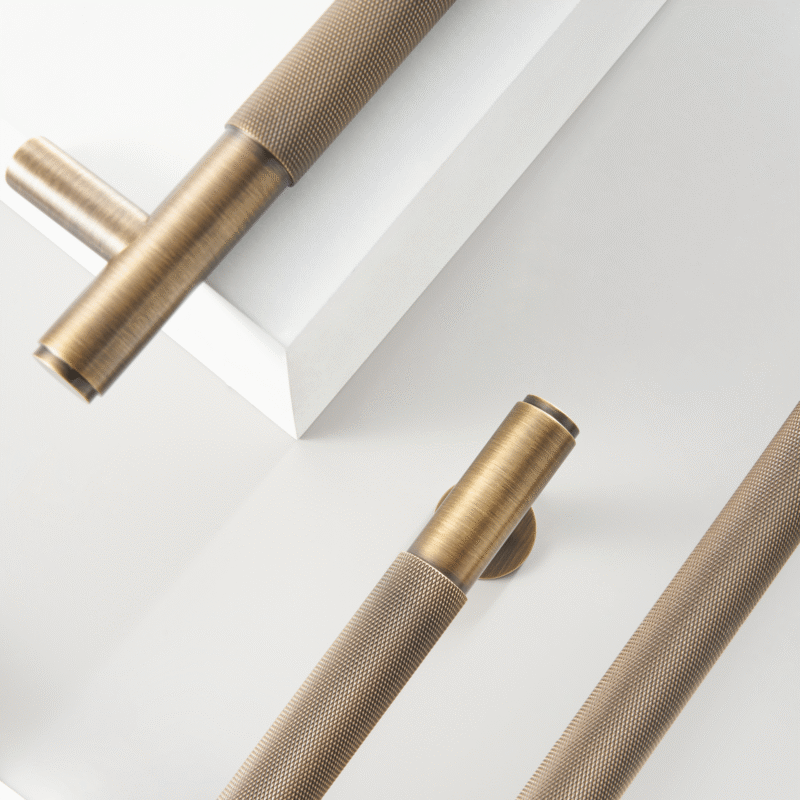

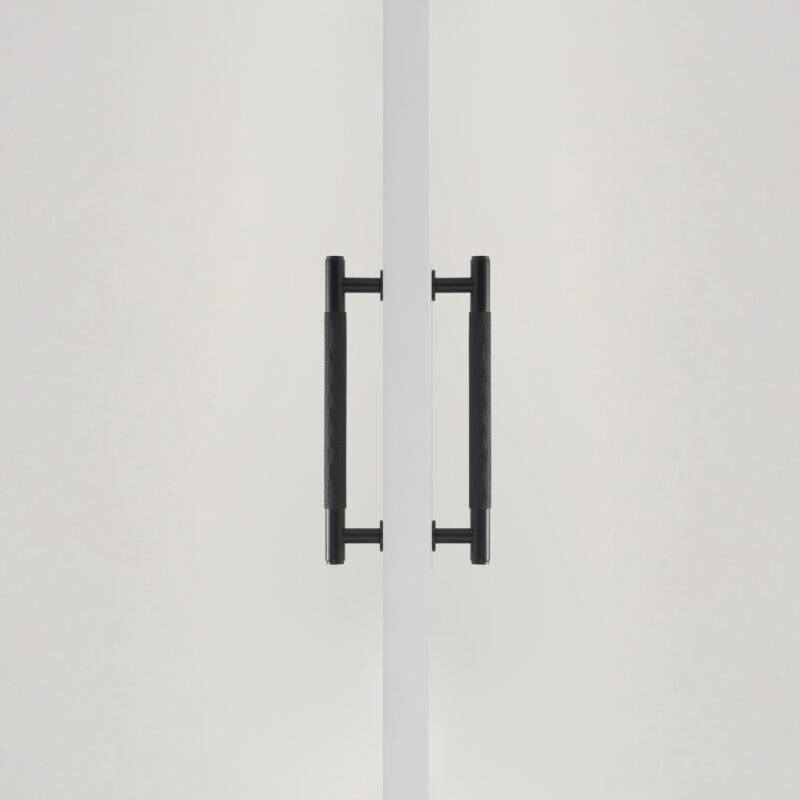

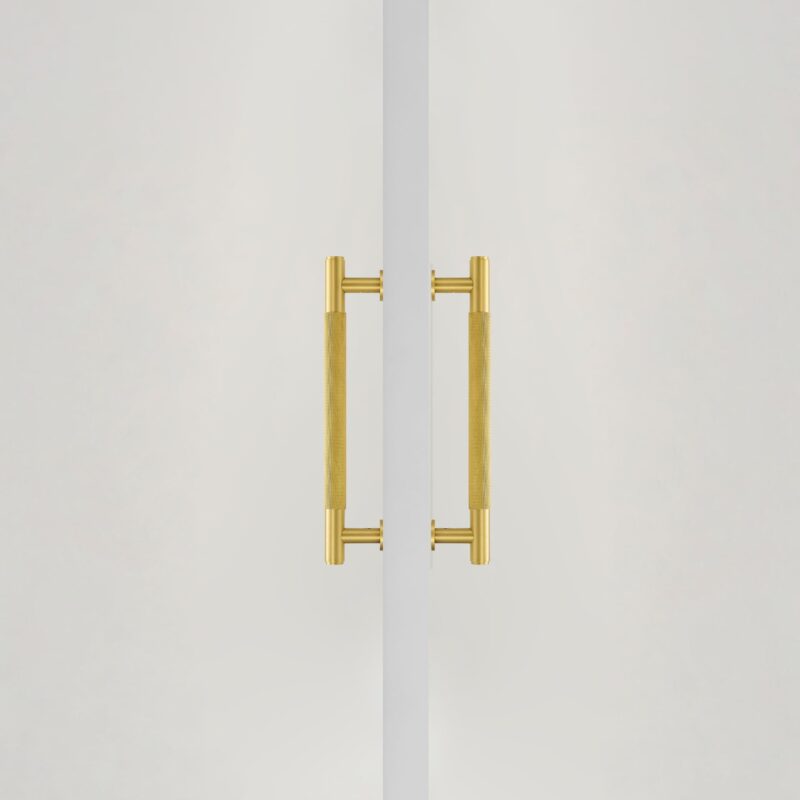

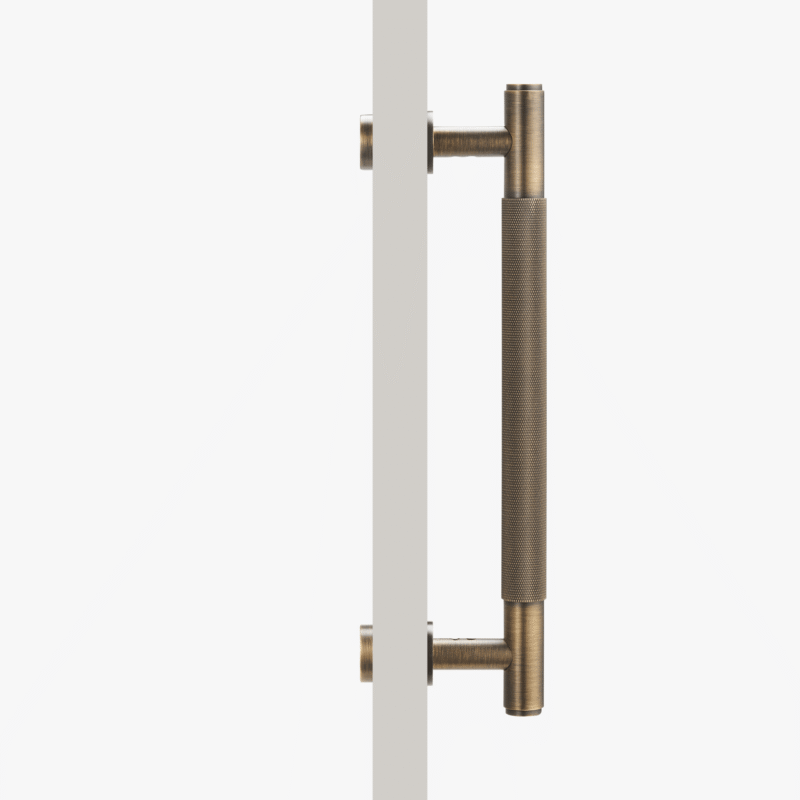

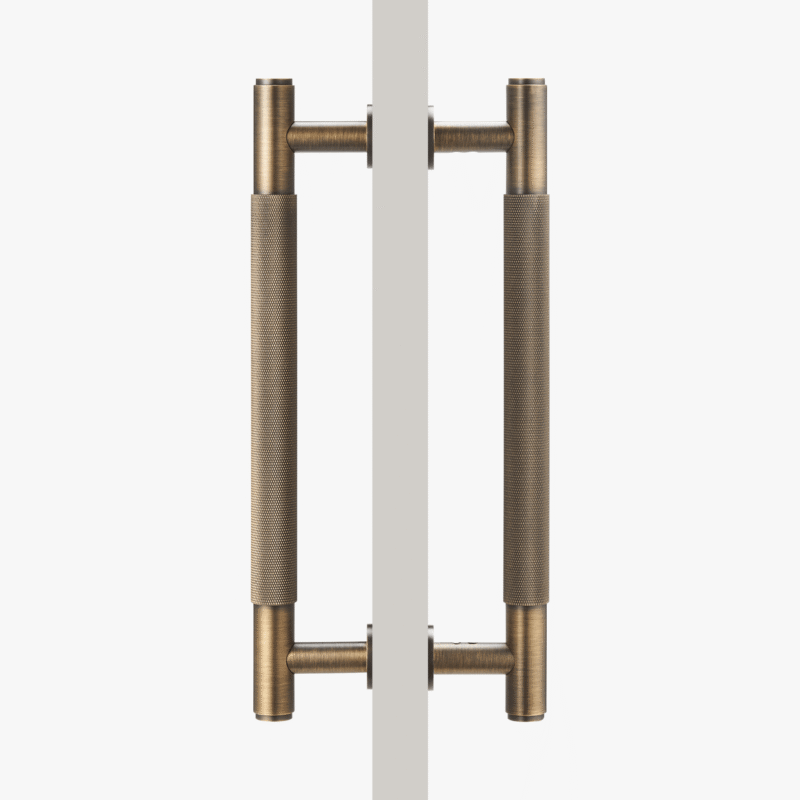

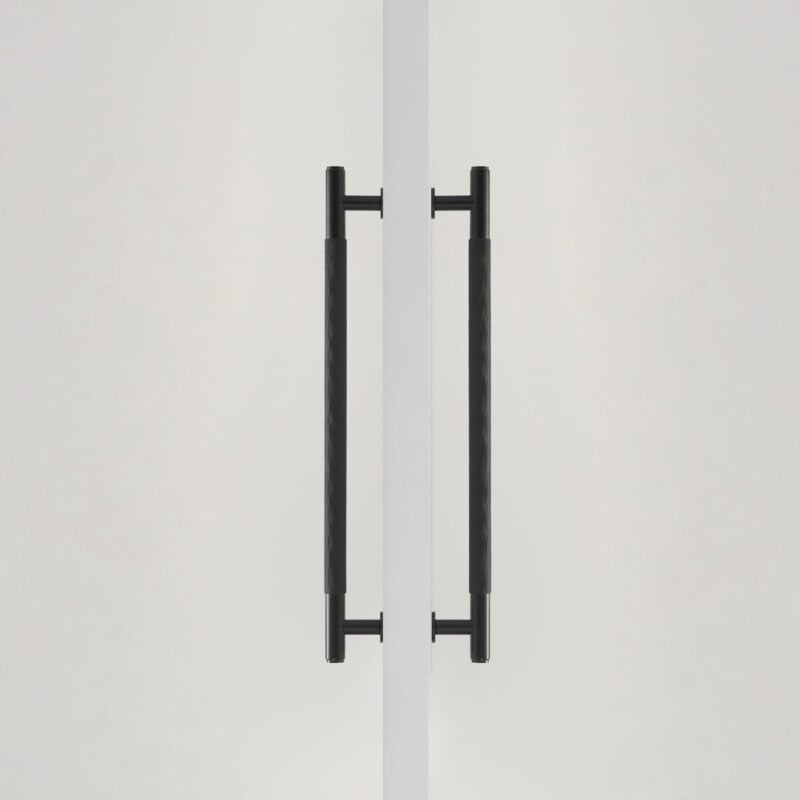

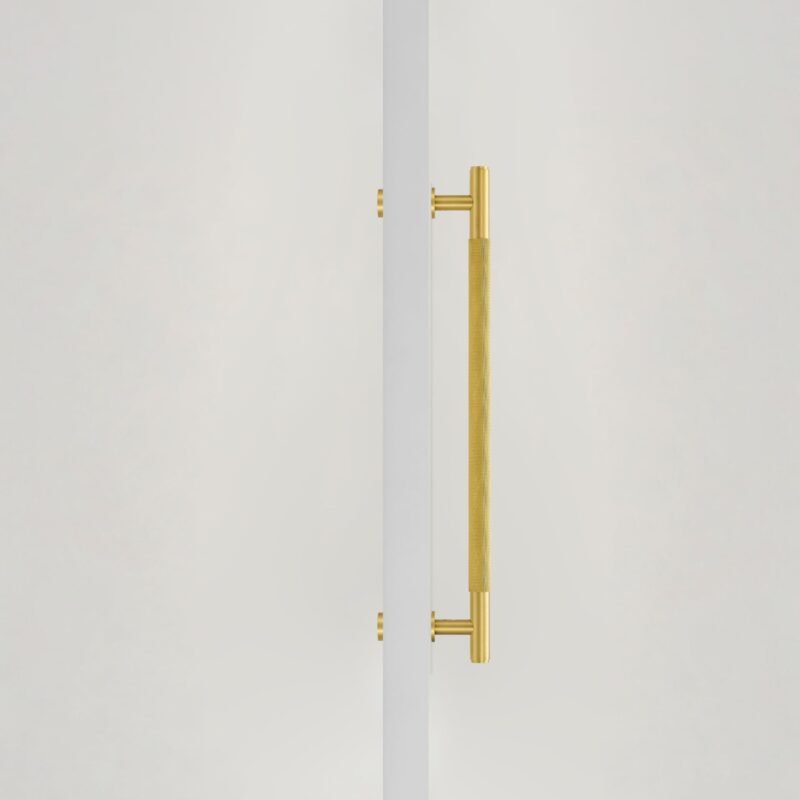

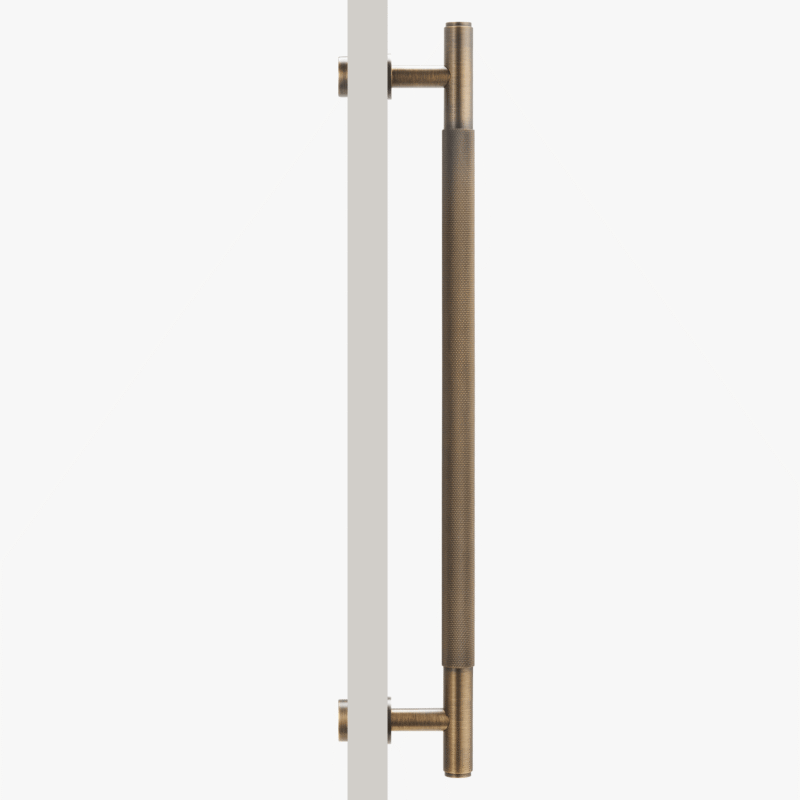

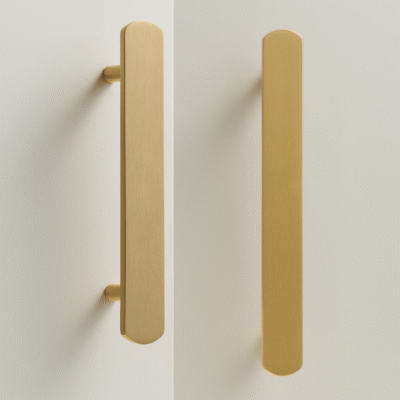

LUX Pull Door Handle

Why You'll Love It

Knurled brass hardware with textured grip. Multiple sizes and finishes available.

| Material | Solid brass |

|---|---|

| Interior / Exterior use | Interior |

| Included | All fixtures needed for installatio |

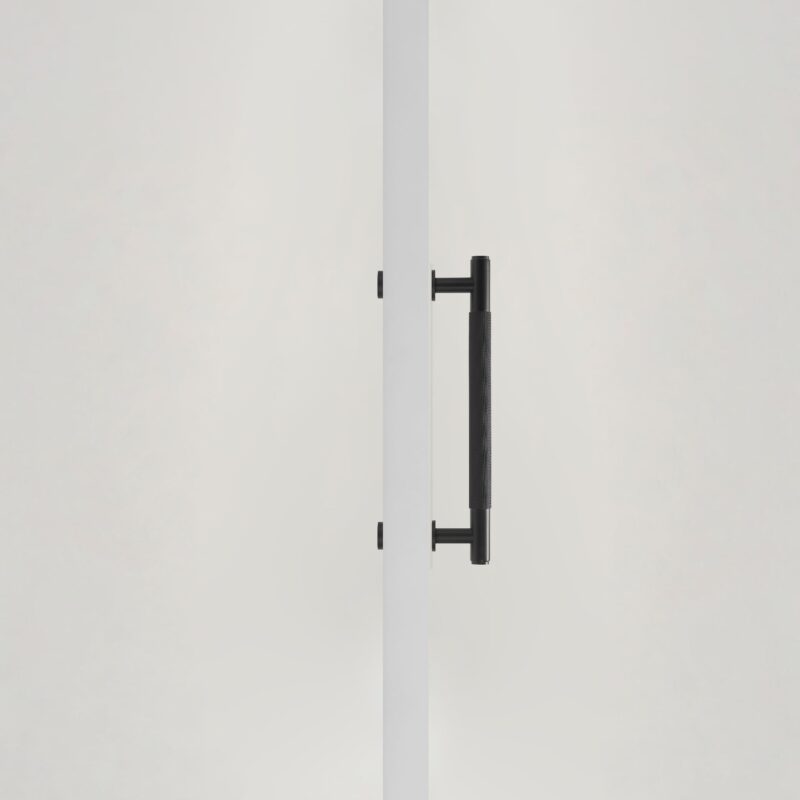

| Compatibility | Purchase a pair to allow two pull handles to be fitted "back to back" on opposite sides of a door, these are suitable for wood doors with a thickness of 35-50mm, 5-23mm for glass doors. Alternatively, the single pull handle is suitable for wood doors with a thickness of 38- 55mm or glass doors with a thickness of 2-18mm. |

| Sold | Individually (per handle) |

| Warranty | 10 Years |

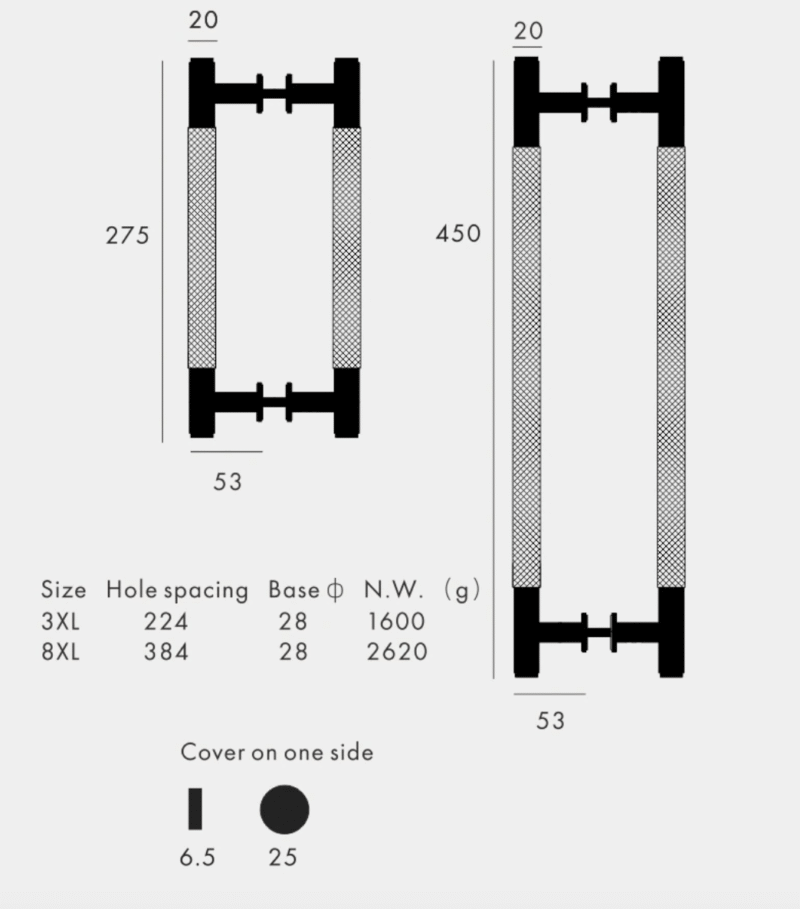

| Height/depth | Length | Distance between holes (CC) | Width of base |

| 53mm | 275mm | 224mm | 25mm |

| 53mm | 450mm | 384mm | 25mm |

Each finish has unique care requirements. Visit our Finish & Care Guide for detailed maintenance instructions.

Standard delivery - 2-4 weeks (4-8 weeks during busy periods). Free worldwide delivery, includes taxes and duties.

Express delivery - 3-14 days. Upgrade available at checkout.

Returns - Made-to-order items cannot be returned unless faulty. All other items are returnable within 90 days of delivery. Must be in unopened and original packaging. 10-year warranty on all products.

Product Story

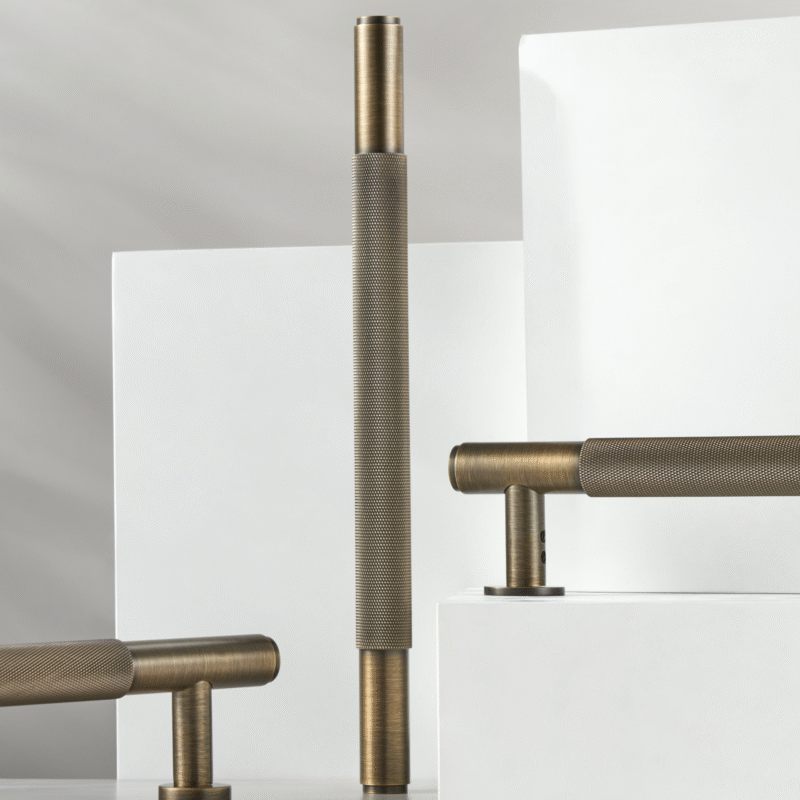

Fine knurling runs the full length, providing secure grip and visual texture. The knurled surface catches light and adds dimension.

Multiple sizes and finishes available to suit different cabinetry applications. Natural aging develops patina over time. Each size maintains the same proportional balance, ensuring visual consistency across different applications.

Where it works best

- Kitchen cabinetry in contemporary schemes

- Bathroom vanities and medicine cabinets

- Bedroom wardrobes and dressing rooms

- Modern furniture requiring refined hardware

Built for daily use. The weight feels grounded in hand. The proportions have been refined through iterative design to ensure comfortable daily interaction.

Made Properly, Not Quickly

We work with specialist manufacturers who understand that hardware isn't just functional—it's the detail people notice. Some pieces are precision CNC-machined from solid brass billets. Others are sand-cast using traditional methods, then hand-finished to remove any imperfections.

The finishing process is where the real craft happens. Each piece passes through multiple stages—grinding, polishing, plating or patinating—before a final inspection under bright light. Finishes like unlacquered brass are left raw to age naturally. Lacquered finishes are sealed to preserve their original tone.

We don't hold stock. Every order is manufactured specifically for you, which means less waste and hardware that hasn't sat in a warehouse for months. It takes a little longer, but the quality is worth waiting for.